Program your machining probe as easily as programming toolpaths with this fully-integrated probing add-on for Mastercam.

Program your machining probe as easily as programming toolpaths with this fully-integrated probing add-on for Mastercam.

CIMCO PROBING virtually eliminates the time associated with external probing software by fully integrating with your Mastercam interface, making it customizable to any type of probe.

CIMCO PROBING has a lower price point than competing probing software and has the navigation advantages of Mastercam’s clean, ribbon interface. Since CIMCO Probing is embedded within the Mastercam programming process, you can run Verify, Backplot and Machine Simulation on the probe. This will assure your probe doesn’t get damaged by avoiding possible collision points before machining.

With logic to adjust while machining, CIMCO Probing can be used for in-process checking for positioning irregularities. The software can even stop your machine if the part is measured out of tolerance.

With the ability to customize parameters, the add-on has a list of predefined Probe Cycles to handle most measurement needs. For added convenience, CIMCO Probing can automatically fill-in parameter values based on the geometry of your stock.

And, upon machining conclusion, CIMCO Probing measures the part in the machine to confirm its dimensions are correct

before the part is unclamped.

Since the CIMCO Probing add-on is integrated within the CNC

programming process, some

modifications may be required to

your post processor. Contact

Dave Meyer at 952-361-5598,

ext.1 or chat with a member of

our local Professional Tech Support Team at ext. 2. CIMCO Probing is an easy and cost-effective solution to help you take full-advantage of your machine’s capabilities.

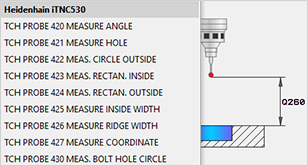

CIMCO Probing includes a wide range of Probe Cycles to handle most measurement needs. Cycles can be customized through user-defined parameters with assisting drawings that make it easy to see what each parameter controls in the cycle. For convenience, CIMCO Probing can intelligently fill in parameter values based on stock model geometry.

CIMCO Probing includes a wide range of Probe Cycles to handle most measurement needs. Cycles can be customized through user-defined parameters with assisting drawings that make it easy to see what each parameter controls in the cycle. For convenience, CIMCO Probing can intelligently fill in parameter values based on stock model geometry.

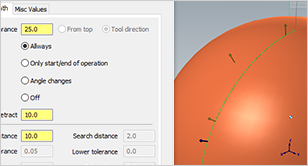

Surface Probing makes it easy to select surface points and surface normals on curved geometry. For any point chosen on the model, a measuring cycle is generated, and the result of the measurements is compared with the 3d model.

Surface Probing makes it easy to select surface points and surface normals on curved geometry. For any point chosen on the model, a measuring cycle is generated, and the result of the measurements is compared with the 3d model.

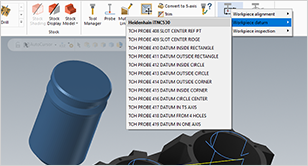

CIMCO Probing works seamlessly inside Mastercam and includes its own dedicated tab in the Ribbon bar with icons for adding Cycle or Surface Probing. Probing options are shown in the Manager Panel and once a cycle is added, it is stored in Mastercam’s Toolpath Manager where it can be repeatedly adjusted as needed.

CIMCO Probing works seamlessly inside Mastercam and includes its own dedicated tab in the Ribbon bar with icons for adding Cycle or Surface Probing. Probing options are shown in the Manager Panel and once a cycle is added, it is stored in Mastercam’s Toolpath Manager where it can be repeatedly adjusted as needed.

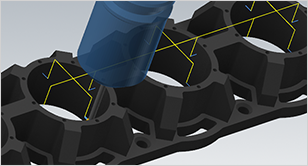

All probe tool movements can be fully visualized and verified using Mastercam’s Backplot, Verify and Machine Simulation. In addition to being convenient, this also provides confidence that your probe tool remains undamaged during machining. Probe tool collisions can be detected and resolved before the program is machined.

All probe tool movements can be fully visualized and verified using Mastercam’s Backplot, Verify and Machine Simulation. In addition to being convenient, this also provides confidence that your probe tool remains undamaged during machining. Probe tool collisions can be detected and resolved before the program is machined.